Dumortierite was originally discovered in the late 1800s by a French mineralogist, who named it after paleontologist, Eugene Dumortier.

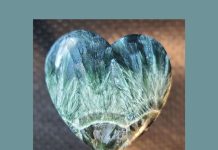

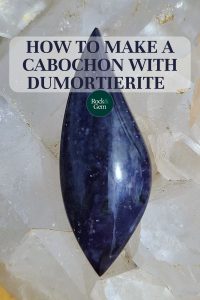

Although most people know this material for its beautiful blue color, it also can be found in pink and violet. Dumortierite can be found in various places across the globe, and at times, has been mistaken for sodalite, or lapis lazuli. Some variations that have gorgeous fibrous dumortierite sprays inside quartz crystals are rare. These tend to be very small pieces, usually ranging from one to five carats. Dumortierite is a good material for lapidary beginners to get hands-on experience. It’s available almost anywhere rocks are sold in a good variety of colors and patterns. It’s fairly hard, usually about seven to eight on the Mohs scale. It also cuts fairly easily.

Tips for Buying Dumortierite

When buying Dumortierite rough, the colors usually show on the outside, but it can have a thin brown rind that can be chipped away to expose the inner color. Many times the blues can be mottled with a lot of white. If a certain hue of blue or continual color throughout is needed, it’s best to buy slabs to be certain.

Cutting Rough Dumortierite

Cutting Rough Dumortierite

When starting out cutting rough, there is no certain direction to load the saw. This is helpful so that it can be loaded in a way that best fits the vice and yield the most material by cutting straight across the entire stone in one direction. Once the slabs are cut, there generally aren’t many fractures in this material. However, it’s always best to bench test before marking up the slabs for preform designs. Either flex the slab in hand to see if it’s stable or lightly tap it against the workbench or ground to see if there are any hidden fractures. This helps to avoid breaking while in the middle of trimming out cab shapes.

Cabbing Dumortierite

Cabbing Dumortierite

Once the preforms are cut and ready for cabbing, be sure to have a dry towel or canned air available to check for scratches along the way. Since towels get damp in a hurry and canned air can start getting expensive, one suggestion is to get a five-gallon air tank with a spray nozzle. It can be continually filled up by a personal air compressor or by a nearby gas station and it will last for quite a while.

Dumortierite tends to quickly show heavy white marks if scratches are still present. I suggest starting on an 80-grit steel wheel to shape and dome cabs and moving to either a 60-grit soft resin wheel or 140 soft resin. This material is fairly hard, so it will take a bit of time to smooth it out and remove all the scratches from the 80-grit wheel. Be sure to dry off occasionally and see if any white scratches are showing.

From this point, move on to the 280-grit soft resin wheel. A white or pale blue haze across the cab is to be expected, but not scratches. Make sure no scratches exist before moving forward. From this point, it’s fair routine to continue cabbing to the 600 grit, all the way up to the 14k grit soft resin wheels.

Finishing Gloss

A 50k grit polishing wheel works great to get an added high-luster gloss. Unless going slow in short increments, it’s not suggested to use polishing compounds on this material. Also, be sure not to allow the material to heat up too much. It can tend to fracture with heat.

This story about dumortierite previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Russ Kaniuth.